machines & artefacts

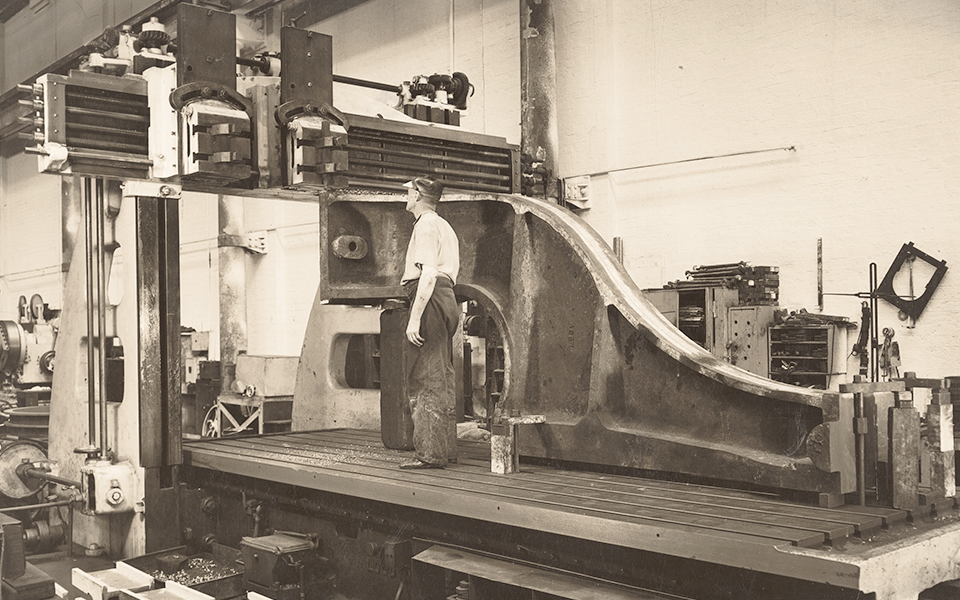

Steam Hammer

This massive cast iron arch steam hammer stands at over 4m tall and is one of the oldest remaining machinery pieces at Eveleigh, installed in 1887 as part of the original steam hammer shop in Bay 1 south. Believed to have been manufactured in the workshops itself, this steam hammer was the largest at Eveleigh, and possibly the largest anywhere in the NSW rail workshops, pounding heated metal with a pressure of 40 cwt (two tonnes).

Read more

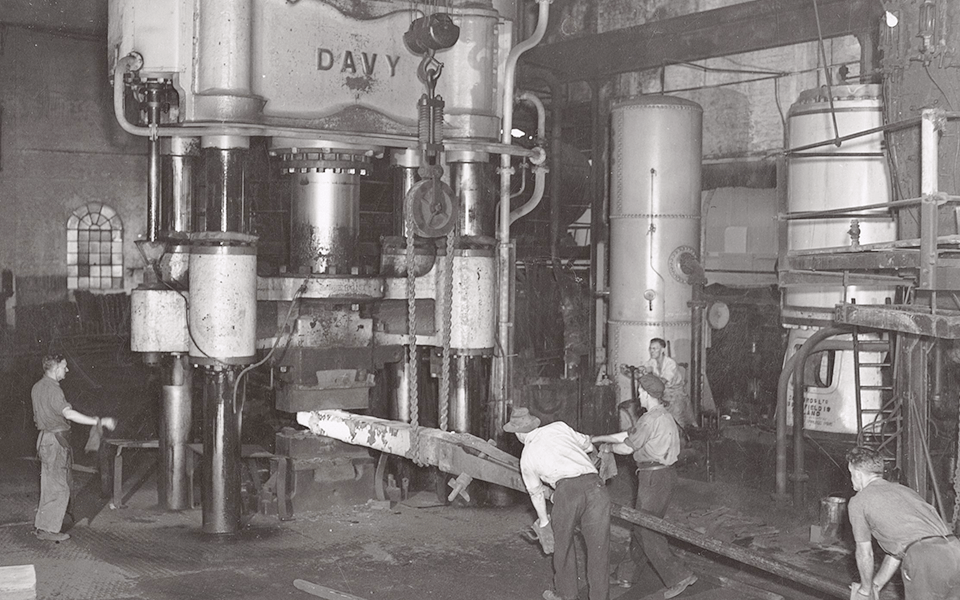

Davy Press Team

The impressive and rare Davy Press—an imposing machine at 6m tall, 2.5m wide and weighing in at an almighty 200 ton—still looms in its original position as part of the Blacksmiths Shop in the north of Bay 1.

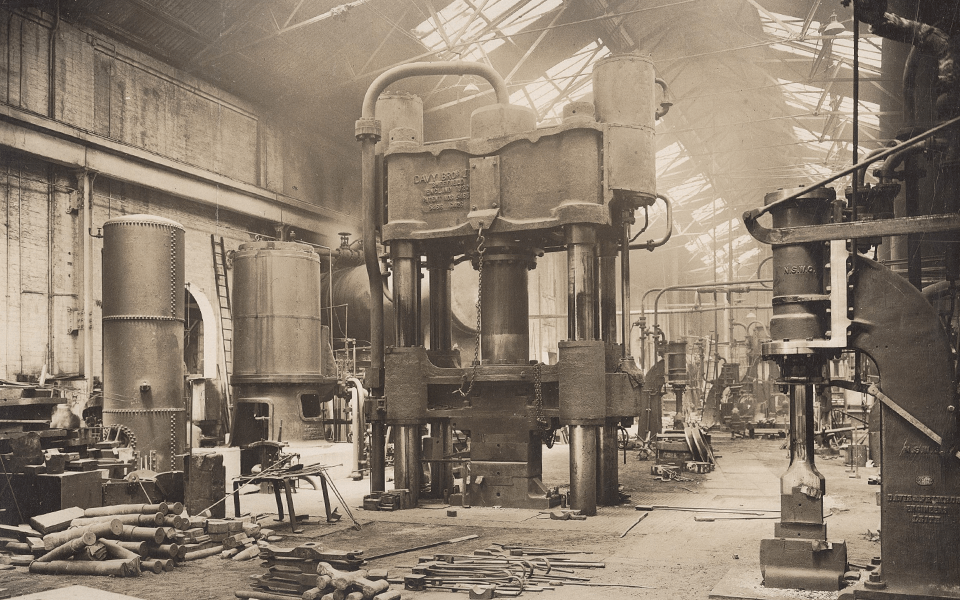

Davy Press

At the time of installation in the Locomotive Workshops Bay 1 in the 1920s, the Davy Press was the largest and most powerful hydraulic press in Australia. Capable of working larger pieces of metal than most of the other steam hammers in the workshops, the Davy Press was used in the production of the largest and heaviest locomotive parts and workshop components made at Eveleigh.

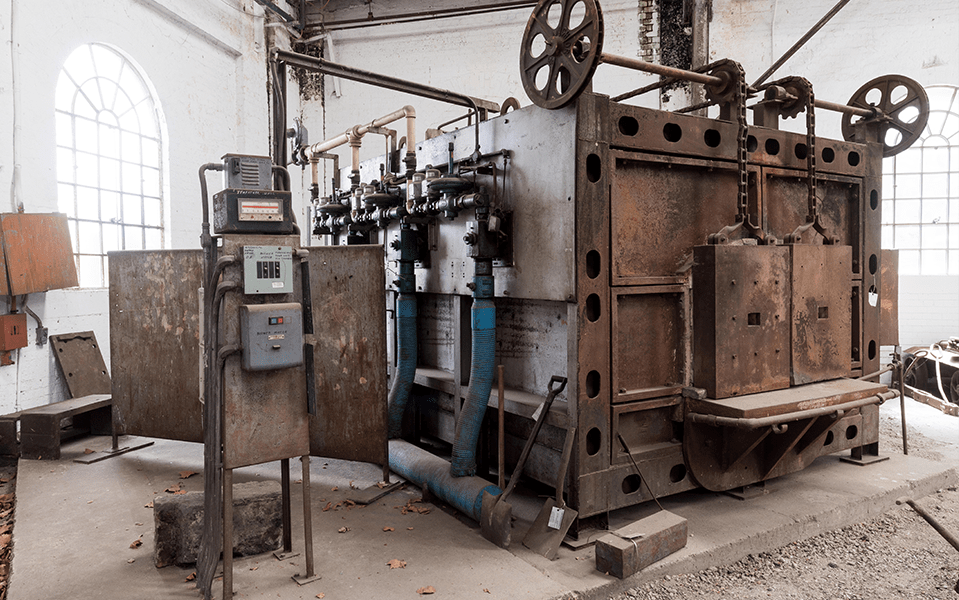

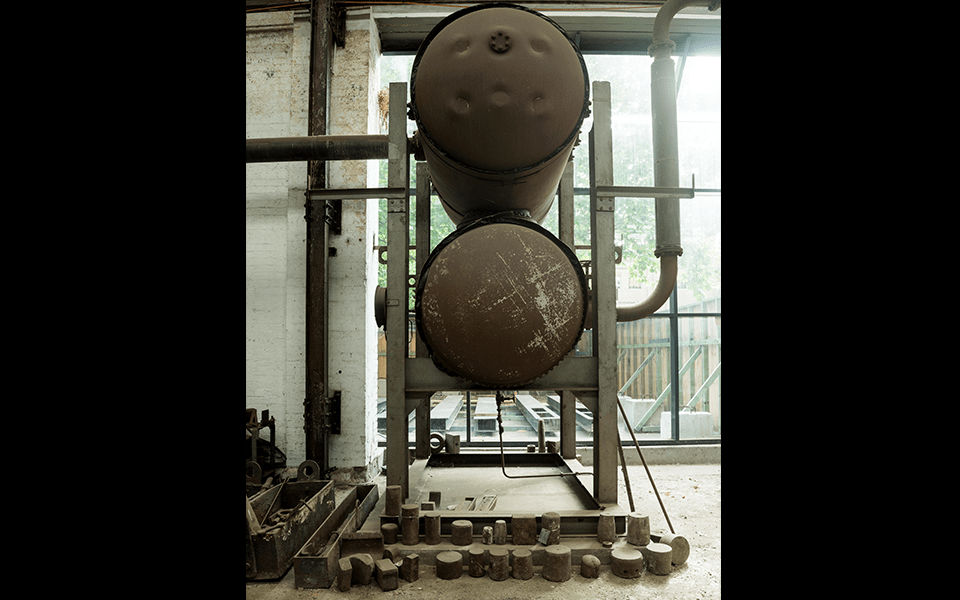

Davy Furnace

Installed in the 1960s around the same time the original furnace boilers were removed, this oil-fired furnace (later converted to burn natural gas) was used to heat the raw metal to be worked on the Davy Press. The large raw steel billets were hauled into the furnace using balanced tongs wielded by the overhead crane.

Craven Bros. Overhead Crane

First installed in the Workshops around 1910, the Craven Bros Overhead Travelling Crane was electrified and relocated to Bay 1 in the 1920s as an essential part of the Davy Press team, used to move heated metal billets between the Davy Furnace and the Press.

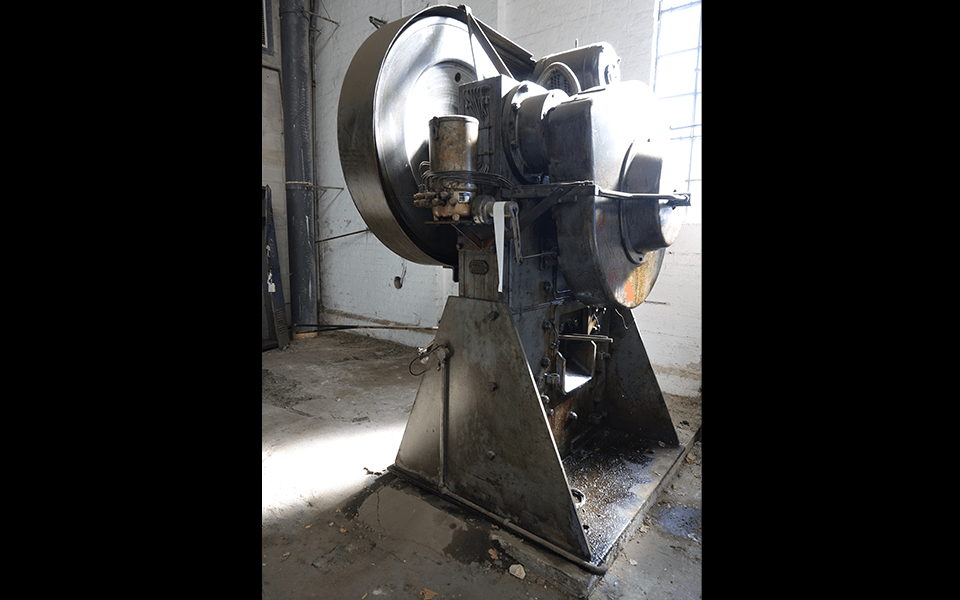

Peddinghaus Shearing Machine

The Peddinghaus Shearing Machine is a large, heavy machine that was mainly used in the Spring Shop for shearing plate or rod metal stock for the production of coiled springs. Installed in the 1950s, the Pedding Haus Shearing Machine was a result of a decision by Eveleigh management at the time to upgrade the equipment in the Spring Shop, improving the spring manufacture process during its peak period of production.

Steam Intensifier

The Steam Intensifier was the power pack for the Davy Press. It was used to further increase the pressure of hydraulic fluid stored in the Hydraulic Reservoir before the fluid could be used to power the Davy Press. The Steam Intensifier is a 3m tall cast iron and steel cylinder that houses a hydraulic piston with a rod connecting to a much smaller cylinder and piston pair.

Read more