Foundry

“This shop manufactured its own finished product, direct from the Aussie drawing board designs: crack express locomotive cylinders, valve chests, centre castings, frame spreaders, tender and carriage parts for the NSW Rail system were all made here”. Richard Butcher, former Eveleigh worker

The 2018 South Eveleigh building ‘The Foundry’ is named for the great Eveleigh Foundry that once stood on this same spot. Responsible for the production of iron, brass and steel castings used for all operations and components for both the locomotive and carriage workshops, the Foundry produced metal items of all sizes, ranging from large bulky cylinders for boilers and larger engine parts, down to the fine delicate fittings used in carriages and wagons.

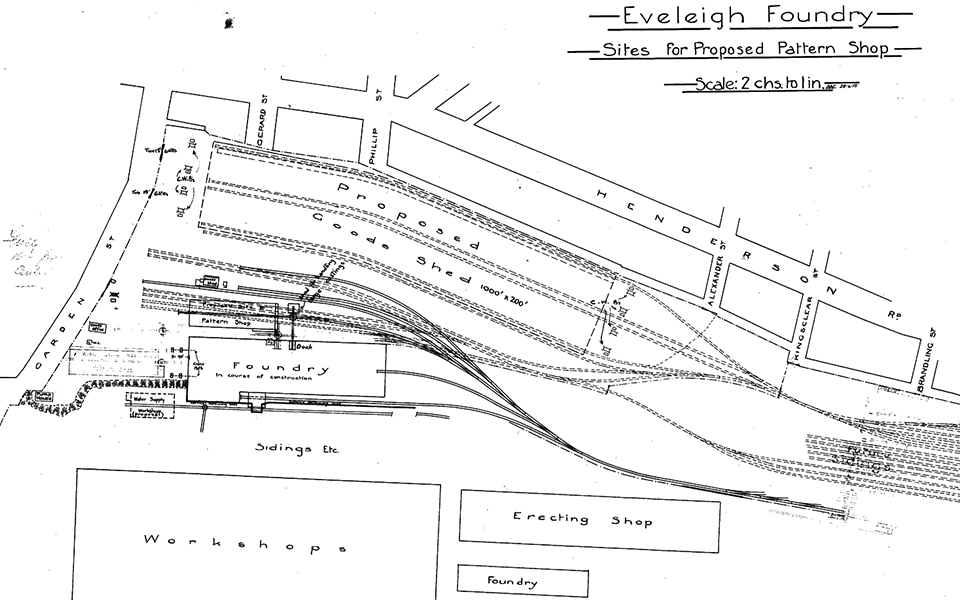

Originally housed in Bay 4, the Foundry, growing quickly in response to the increasing demands of the rapidly developing Railway Workshops, was soon relocated in 1893 to a standalone building at the southern end Bay 15. The Foundry’s third, final and largest home was in a corrugated-iron roofed and clad, sawtooth roofed building that opened in 1917 on the eastern side of the Locomotive Workshops.

The Foundry was divided into three distinct areas: the main Iron Foundry; smaller Brass Foundry along western side; and Steel Foundry in the south. Rail track and turntables linked the Foundry with the neighbouring pattern shop and store building to the north, so the large foundry patterns could be readily transported to and from the Foundry for use.

“The floor was dirt and sand littered with mounds of sand and casting boxes; it looked like a cemetery, with dull grey mullocks spread across the foundry floor” Richard Butcher, former Eveleigh worker

Work in the Foundry casting all kinds of metal components used in the everyday function of the Locomotive and Carriage Workshops was hot, dirty and dangerous. Overhead travelling cranes moved towering vats of molten liquid metal from the furnaces to pour into the hundreds of mould boxes arranged in regimental lines across the dirt and concrete floor.

“A visitor to the foundry would be pardoned for imagining that he was looking at one of the circles of Dante’s inferno, for no other description would more aptly describe the conditions that human beings work under there.” The Labor Daily, 15 December 1925

With the decline of steam locomotion in favour of diesel engines in the 1960s and 1970s, an attempt was made in the 1970s to prolong the Foundry’s productivity by upgrading facilitates to focus production on more generalised and high-volume castings (e.g. brake blocks, signal components, centre castings, suspension bearings) over traditional bespoke pieces. However, despite technological innovation to maintain relevance, and the efforts of unions to save it, the Foundry eventually closed in the 1980s along with the rest of the Eveleigh Railway Workshops, and demolished in 1988.

References

Dalton, J. & Saunders, B., ARHS NSW, 16 April 2018, “Eveleigh Foundry- A brief History”

1925 'CARD AND BONUS', The Labor Daily (Sydney, NSW : 1924 - 1938), 15 December, p. 2. , viewed 10 May 2021, http://nla.gov.au/nla.news-article239869136