Blacksmith’s Workshop

“Here, all the heavy forgings are made for renewals and repairs…Seven steam hammers, ranging in power from five cwt to forty cwt work multifarious devices out of shapeless masses of heated iron; their stroke varying from a gentle catspaw-like caress, to a concussion like a thunderbolt.” Illustrated Sydney News, 18 July 1891

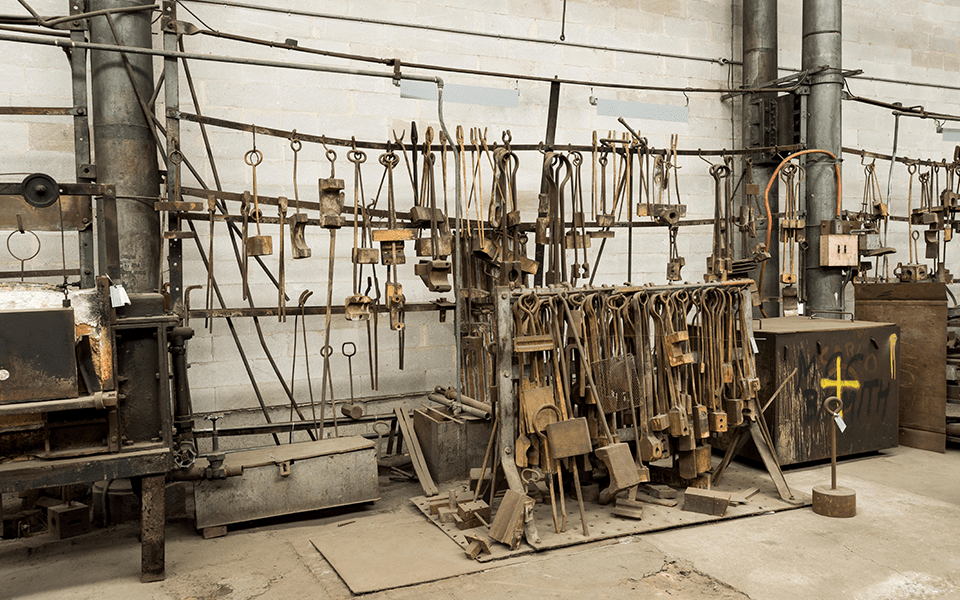

Among the first trades to commence operation at Eveleigh Locomotive Workshops in 1887 was the Blacksmith’s Shop in Bays 1 and 2—Eveleigh’s centre of metal forging. Many of the Blacksmithing steam-era tools remain on display today in Bays 1 and 2, several of which sit in the exact same location they have been for over 100 years.

The Blacksmith Shop was filled with an assortment of Victorian era smithing steam and pneumatic hammers, razor sharp guillotines and electric shears, smouldering forges and furnaces, and numerous other tools, all used daily by skilled blacksmiths in their metal working tasks.

Steam to power the massive hammers was produced by four large boilers outside Bay 2 and channelled into the Blacksmith Shop through overhead metal pipes that threaded through the bays, steam whooshing from the boilers to the Victorian machinery it powered.

“The “bang-bang-bang” was deafening and sparks flew everywhere: entering your ear holes, burning your hair, singeing the eyebrows, hurting your pride, but you’re right in the centre of the action!” Richard Butcher, former Eveleigh Worker

Under extreme temperatures, tar ignites, wood burns, and concrete explodes. So, while concrete slabs were laid for flooring across other Bays, Bays 1 and 2 Blacksmiths continued to work on a rammed-earth ground, all the better to avoid the floor catching on fire.

“The floors were dirt and there was always a mist of burning coal in the air.” Richard Butcher, former Eveleigh Worker

Forges with cast iron hoods and water-cooled air inlets served cast iron fire-beds covered in firebrick, and fires were continuously fanned by air driven through underground pipes across the workshop, supplied by special air blower machines installed against the south wall. Anvils stood at the ready to receive deafening blows, while coke fuel bins were constantly filled, ready to feed the forges. Many thousands of special tools for wielding and shaping metal were constantly within reach of a blacksmith’s hand—tongs, swage blocks, dies, hammers, drifts and punches.

Although the Locomotive Workshops ceased operation in 1989, the Blacksmithing tradition in Bays 1 and 2 of over 100 years lived on, with a blacksmith in residence continuing to operate in Bay 1 south, actively using parts of the original Eveleigh blacksmithing tools, furnaces and presses even today.

References

Butcher, R.K. & Murphy, L (ed). (2004). The great Eveleigh railway workshops: a personal reminiscence. Richard Butcher Eastwood, NSW

1891 'The N.S.W. Railway Workshops at Eveleigh.', Illustrated Sydney News (NSW : 1881 - 1894), 18 July, p. 11. , viewed 19 May 2021, http://nla.gov.au/nla.news-article63616851